Basic Info.

Model NO.

Ply456

Using Time

10 Times-30 Times

Density

780-790

Shipment

in 15 Days

Production One Day

2000 PCS/Day

Transport Package

Pallet Packing

Specification

1220*2440, 915*1830, 1250*2500

Trademark

DFW-Y005

Origin

China

HS Code

4412310090

Production Capacity

5000cbm/Month

Product Description

EXCELENT QUALITY OF CONSTRUCTION FILM FACED PLYWOOD

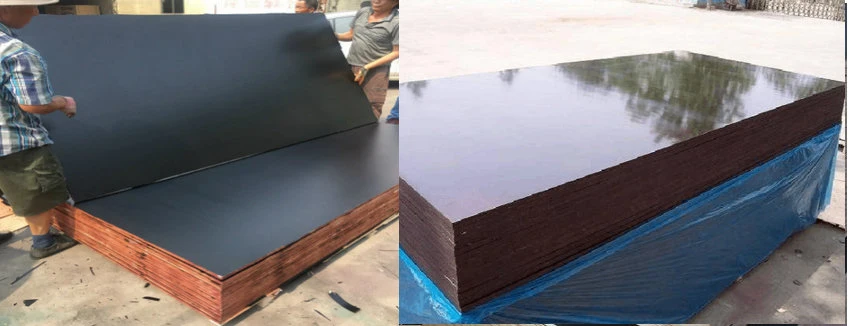

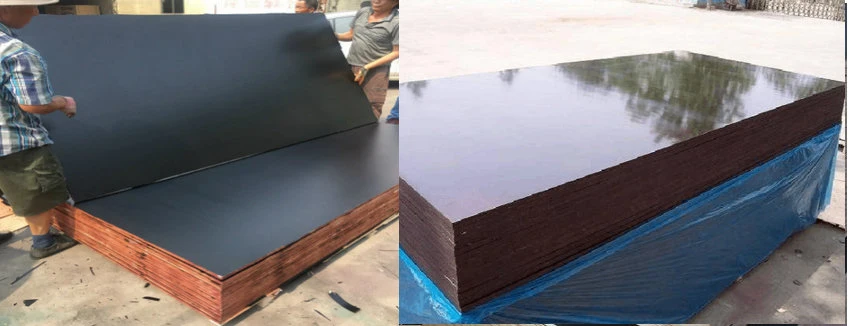

PRODUCTS SHOW:

WHOLE AND GOOD CORE:

USED THE BEST MATERIALS AND BEST MANUFACTURING TECHNIQUE.

GOOD QUALITY USED IN CONSTRUCTIONS :

PALLET PACKAGE AND LOADING:

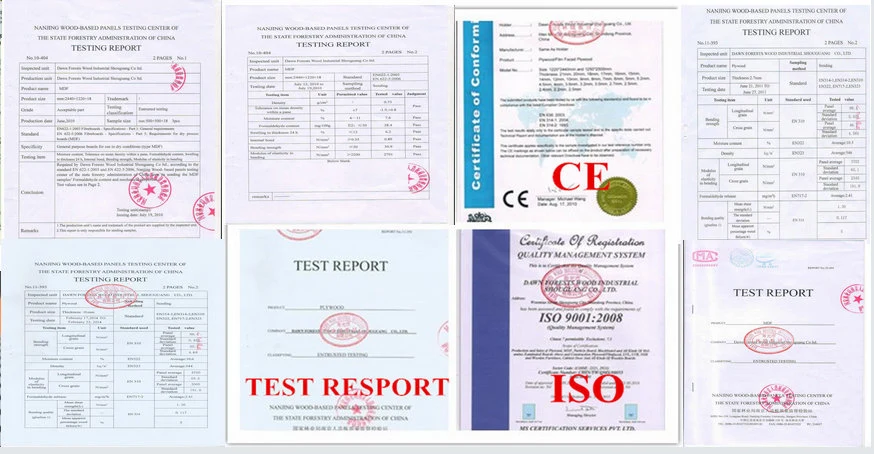

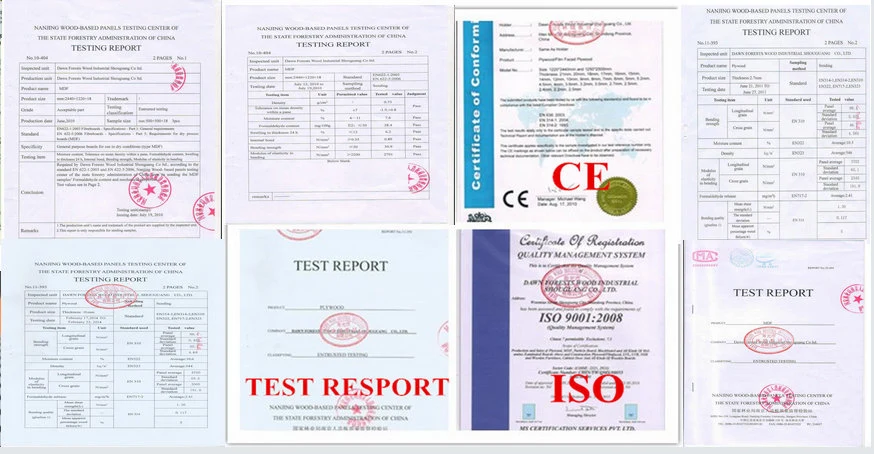

CERTIFICATE FROM US :

REGARDING OUR COMPANY

Dawn forests wood industrial shouguang co Ltd, established in 2002, is a leading manufacturer of plywood/construction plywood for years, plywood factory (located in linyi city, Shandong province) occupied workshop area 25, 000 Square meter, production capacity 30, 000 meter cubic annually. Since May 30th 2012, our particle board production line (located in Shouguang city, Shandong province) started to work, with workshop area 100, 000 Square meter, annual production capacity 60, 000 meter cubic.

Plywood is a manufactured wood panel made from thin sheets of wood veneer. It is one of the most widely used wood products. It is flexible, inexpensive, workable, re-usable, plywood is used instead of plain wood because of its resistance to cracking, shrinkage, splitting, and twisting/warping, and its general high degree of strength.

Plywood layers (called veneers) are glued together with adjacent plies having their wood grain at right angles to each other to form a composite material. cross-graining has several important benefits: it reduces the tendency of wood to split when nailed at the edges, it reduces expansion and shrinkage equating to improved dimensional stability, and it makes the strength of the panel consistent across both directions. There are usually an odd number of plies so that the sheet is balanced_this reduces warping. Because of the way plywood is bonded (with grains running against one another and with an odd number of composite parts) it is very hard to bend it perpendicular to the grain direction.

Particleboard or chipboard is manufactured by mixing wood particles or flakes together with a resin and forming the mix into a sheet. The particles are first dried, after which any oversized or undersized particles are screened out, then the resin has been mixed with the particles, the liquid mixture is made into a sheet. The sheets formed are then cold-compressed to reduce their thickness and make them easier to transport. Later, they are compressed again, this process sets and hardens the glue. All aspects of this entire process must be carefully controlled to ensure the correct size, density and consistency of the board. The boards are then cooled, trimmed and sanded. They can then be sold as raw board or surface improved through the addition of a wood veneer or laminate surface.

RFQ:

1. You are factory or trader?

We are factory, aslo dealing some trading business to supply one-stop service , resources integration,this can save a lot of time & cost to client.

2.Where is your factory ?

Our factory of melamine mdf , located in shandong povince , it can be arrived by car or train from shanghai. Our import & export company is in weifang..

3.What about delivery time & MOQ?

melamine mdf Usuallu MOQ Is 20FCL, some not normal products should be above 300CBM. It will be delivery 10-30 days depond on the quantity.

4. What is your payment terms of melamine mdf ?

We accept 100%TT, 30/70TT, LC A/S, can start business by CIF,CFR,FOB,EXW,CIP etc.

5.Do you privide samples?

Yes, we can confirm sample firstly, then start business as sample quality, usually sample is free, but you might to pay the postage, it can be deduct after start business.

6.Do you accept OEM?

Yes, our brand or OEM both are acctable.

OUR CUSTOMERS AND VISITING EXHIBITION:

| Film Faced Shuttering Plywood/Construction Formwork Plywood/Concrete Formwork Plywood/Marine Plywood | ||

| Size | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm Or as clients requirement | |

| Thickness | 9mm,12mm,15mm,18mm,21mm etc, | |

| Core: | Poplar, Hardwood, Birch , Combi etc, | |

| Film | Dynea(import)brown film ,brown(domestic)film, black(domestic) film,red film, yellow film , | |

| Length(width) tolerance | +/-0.2mm | |

| Thickness tolerance | +/-0.5mm | |

| Processing of edge | By warterproof painting in diffirent colors | |

| glue | WBP(phenolic) MR(water proof) MELAMINE(water proof) | |

| Mositure content | 8%-12% | |

| Density | >550-650KGS/CBM | |

| Modulus of rupture | >30MPa | |

| Modulus of Elasticity | >6000MPa | |

| packing | bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

| quantity | 20GP | 8pallets/21M3 |

| 40GP | 16pallets/42M3 | |

| 40HQ | 18pallets/53M3 | |

| Usage | Usage adequate for making construction formwork plywood, concrete formwork plywood,marine plywood etc | |

| Minimum Order | 1*20GP | |

| Payment | TT or L/C at sight | |

| Delivery Time | Within 20 days receiving deposit or original L/C at sight | |

PRODUCTS SHOW:

WHOLE AND GOOD CORE:

USED THE BEST MATERIALS AND BEST MANUFACTURING TECHNIQUE.

GOOD QUALITY USED IN CONSTRUCTIONS :

PALLET PACKAGE AND LOADING:

CERTIFICATE FROM US :

REGARDING OUR COMPANY

Dawn forests wood industrial shouguang co Ltd, established in 2002, is a leading manufacturer of plywood/construction plywood for years, plywood factory (located in linyi city, Shandong province) occupied workshop area 25, 000 Square meter, production capacity 30, 000 meter cubic annually. Since May 30th 2012, our particle board production line (located in Shouguang city, Shandong province) started to work, with workshop area 100, 000 Square meter, annual production capacity 60, 000 meter cubic.

Plywood is a manufactured wood panel made from thin sheets of wood veneer. It is one of the most widely used wood products. It is flexible, inexpensive, workable, re-usable, plywood is used instead of plain wood because of its resistance to cracking, shrinkage, splitting, and twisting/warping, and its general high degree of strength.

Plywood layers (called veneers) are glued together with adjacent plies having their wood grain at right angles to each other to form a composite material. cross-graining has several important benefits: it reduces the tendency of wood to split when nailed at the edges, it reduces expansion and shrinkage equating to improved dimensional stability, and it makes the strength of the panel consistent across both directions. There are usually an odd number of plies so that the sheet is balanced_this reduces warping. Because of the way plywood is bonded (with grains running against one another and with an odd number of composite parts) it is very hard to bend it perpendicular to the grain direction.

Particleboard or chipboard is manufactured by mixing wood particles or flakes together with a resin and forming the mix into a sheet. The particles are first dried, after which any oversized or undersized particles are screened out, then the resin has been mixed with the particles, the liquid mixture is made into a sheet. The sheets formed are then cold-compressed to reduce their thickness and make them easier to transport. Later, they are compressed again, this process sets and hardens the glue. All aspects of this entire process must be carefully controlled to ensure the correct size, density and consistency of the board. The boards are then cooled, trimmed and sanded. They can then be sold as raw board or surface improved through the addition of a wood veneer or laminate surface.

RFQ:

1. You are factory or trader?

We are factory, aslo dealing some trading business to supply one-stop service , resources integration,this can save a lot of time & cost to client.

2.Where is your factory ?

Our factory of melamine mdf , located in shandong povince , it can be arrived by car or train from shanghai. Our import & export company is in weifang..

3.What about delivery time & MOQ?

melamine mdf Usuallu MOQ Is 20FCL, some not normal products should be above 300CBM. It will be delivery 10-30 days depond on the quantity.

4. What is your payment terms of melamine mdf ?

We accept 100%TT, 30/70TT, LC A/S, can start business by CIF,CFR,FOB,EXW,CIP etc.

5.Do you privide samples?

Yes, we can confirm sample firstly, then start business as sample quality, usually sample is free, but you might to pay the postage, it can be deduct after start business.

6.Do you accept OEM?

Yes, our brand or OEM both are acctable.

OUR CUSTOMERS AND VISITING EXHIBITION: